ICAR-CIFT establishes Clam Processing Facility for fisherwomen

|

|

|

Inauguration by Hon’ble Minister for Fisheries, Harbour Engineering & Cashew Industry, Government of Kerala, Smt. J MercykuttyAmma.

|

Unveiling of the inaugural plaque in the presence of Adv. A.M Ariff, Hon’b;e MP, Alappuzha

|

A Clam Processing Facility was set up by ICAR-CIFT at Perumbalam Island in Alappuzha district of Kerala for the benefit of clam fisherwomen. About 250 families in the village,dependent on clam fishery for their livelihood, will directly benefit from this initiative. The facility was set up under a project funded by SEED Division, Department of Science & Technology, New Delhi. The facility was inaugurated by Hon’ble Minister for Fisheries, Harbour Engineering& Cashew Industry, Government of Kerala, Smt. J MercykuttyAmma on 20 Sept., 2019, in the presence of Hon’ble MP, Alappuzha Adv. A.M.Arif. The project implemented in a participatory mode involved the PerumbalamGrama Panchayat and the Haritha Farmers’ Club form the village.

On this occasion Director, ICAR-CIFT Dr. Ravishankar C.N. in his address apprised the gatherings about the importance of the clam processing facility and told that the project has been able to standardize protocols for processing clam; develop and demonstrate value added products; design and fabricate customized machinery required for the processing; build capacities of the local people; and establish the clam processing facility. Director, ICAR-CIFT appreciated the efforts of the project team comprised of Dr. Nikita Gopal, Principal Scientist, Dr. Bindu J, Principal Scientist and Shri. S. Sreejith, Scientist and Shri. V. Chandrasekar, Scientist for a participatory mode of technology dissemination.

Hon’ble Minister for Fisheries, Harbour Engineering& Cashew Industry, Government of Kerala, Smt. J Mercykutty Amma lauded the efforts of ICAR-CIFT for its successful technology intervention in fisheries to bring livelihood security, which can be a model for the other areas.

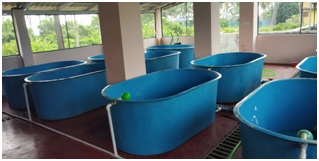

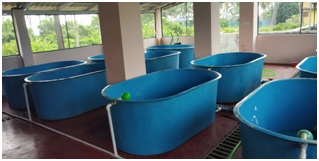

The clam processing facility is a fully integrated one, including depuration tanks system for depurating clams; processing hall equipped with tables, flake ice machine, chill room; a cooking-cum-boiler unit for cooking and shucking the clams; and a meat-shell separator for mechanically separating the meat from the shell. The facility will be able to produce depurated, safe, cleaned, packed clam product that can fetch a premium price in the market. Product diversification that was demonstrated can be an added income generating activity that can be taken up by the cluster members. Currently the clam processing facility is fully functional with test operations and test marketing successfully completed. 90 fisherwomen of 5 clusters formed under the project have been trained and hands-on training on GMP (Good Manufacturing Practices) as well as preparation of value added products.

|

|

| Depuration System |

|

|

|

|

| Capacity Building Program |